Welcome to visit SONYAN Freeze Dryer Manufacturer official website!

E-mail:

service@bjsyhx.com.cn

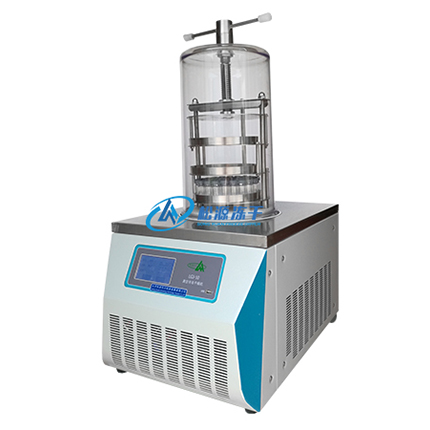

The pilot-type freeze dryer is also called a pilot-type freeze dryer and a pilot-type vacuum freeze dryer. It can be divided into two types: normal type and gland type. Suitable for small batch production, it can provide a feasible solution for formal large-scale freeze-drying production. It is suitable for vacuum freeze-drying of high-grade raw materials, Chinese herbal medicines, biological, wild vegetables, dehydrated vegetables, food, fruits, chemicals, pharmaceutical intermediates and other materials.

The difference between the small freeze dryer and the pilot freeze dryer?

A. When a small number of small freeze dryers are lyophilized, pay attention to whether your post-treatment method can be carried out in batch-test lyophilization. It should not be done only for lyophilized products. Consider the feasibility of operation, for example, oil. The treatment, in the small bottle, the vial is easy to get, what about the big bottle? The pilot-type freeze dryer is generally only for solid or liquid transfer, and the post-treatment method should satisfy this requirement as much as possible.

B. When the small freeze dryer is lyophilized in a small amount, it is necessary to do a good job in material calculation, especially in the post-treatment. There must be an economic and cost mind. In batch or mass production, the work must be planned and predictable. Prevent in advance!

Comments: The post-treatment of the pilot-type freeze dryer is different from the chemical reaction that cannot be tested in the small-scale freeze dryer. Therefore, the researcher must have the pilot experience and understand the freeze-drying equipment. In the experiment, we should consider the problems that may be encountered in the pilot-type freeze dryer, and imagine the feasibility of post-treatment.

Where is it generally used? Beijing Songyuan pilot-type freeze dryer is generally used in 1. Research institutes 2. Fine chemical enterprises 3. Pharmaceutical enterprises 4. Small-scale production enterprises. ,

Features:

★ Pre-freeze drying is carried out in situ to reduce the complicated operation of the drying process and realize automation;

★The lyophilizer has an observation window inside, and the drying process is intuitive.

★ Touch screen LCD display, PID intelligent adjustment, display the drying process in the form of curves and data, and provide users with more information about the drying process.

★ Self-cascading refrigeration technology, imported brand compressors ensure low noise, large cooling capacity and large water catching capacity of the equipment, reducing freeze-drying time.

★ Square stainless steel shelf is not easy to deform, easy to operate and easy to clean.

★The lyophilization chamber adopts high-quality, high-strength, high-light-transparent, colorless and transparent plexiglass door, which can clearly observe the material change process during operation.

★The cold trap and working surface are made of stainless steel, which is easy to clean and corrosion resistant.

★The shelf is made of silicone oil, the temperature error is 1 °C, and the drying effect is even;

★ shelf temperature adjustable, controllable, groping pilot and production process;

★Configure the inflation valve to fill the dry inert gas;

★Optional eutectic point test device; automatic pressure plug device; temperature recorder